Load monitoring reduces risk of fatigue

The EMS solutions from Leine Linde are measuring strain for the optimization of wind turbine control and condition monitoring. EMS stands for Elongation Measurement System, and consists of strain sensors together with a central evaluation unit to help with reading out and analyzing the values. This solution is ready to be installed in wind turbines or other applications.

Modern wind turbines are subject to stronger loads due to turbulent wind flows and the ever increasing size of rotors. When the wind turbine uses individual pitch control (IPC), the load on individual components increase, as the turbine should be optimized for energy harvesting. This may cause material fatigue if the loads and effects on the structure are not carefully monitored by help from sensors.

For the rotor blade, machine frame, and tower

With the EMS Elongation Measurement System, the structural loads are monitored and measures can be taken for long-term sustainable care. Structural load can be measured, including dynamic load changes, on the rotor blade, machine frame, and tower of a wind turbine. This data can be used to increase the availability and lifespan of wind turbines.

Hardware and software

The hardware of the system is customized for the application with regard to the size and complexity, with a combination of strain sensors and gateway products which are connected to a process diagnostic box, a PDB. The supplied software has function modules for plausibility check of the sensor data, calibration, system error checking and monitoring of the material strain limits.

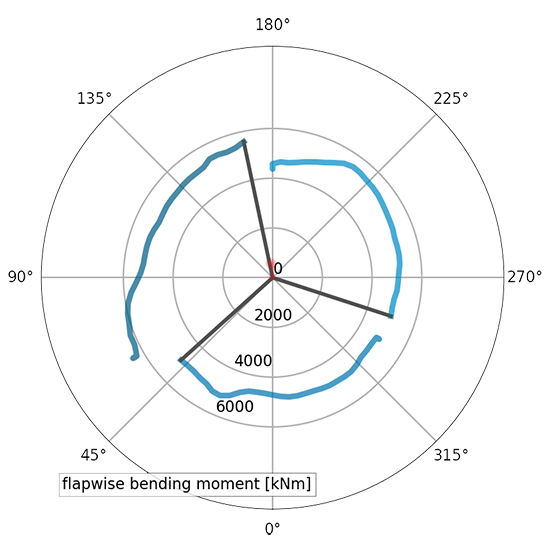

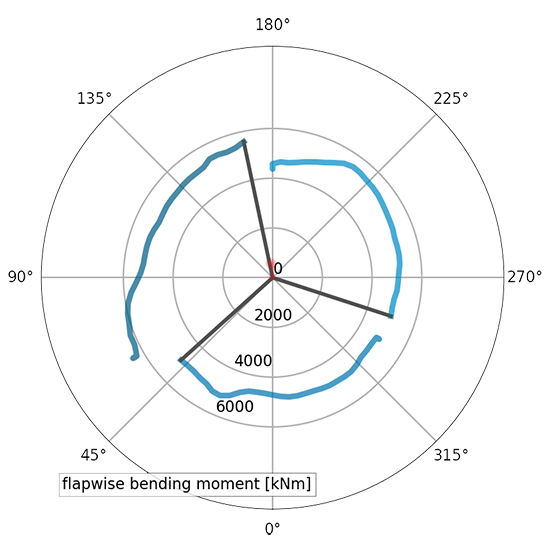

There is also a ready-to use application module, which calculates lateral and longitudinal bending moments of each rotor blade, which can be shown in a web-based user interface.