Leine Linde expands the measuring lengths for steel and aluminium milling

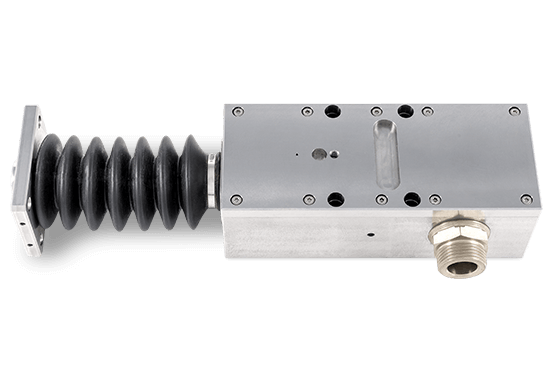

The robust linear encoders RLI 4300 with their associated ERG gateway for digital or fieldbus communication are now released with additional measurement lengths. Developed for metal hot rolling, the encoders withstand high temperatures, shock, vibration, liquids and chemicals. Answering to the users’ demand, the measuring lengths 170 mm and 260 mm have now been added to the product series. This makes the measuring system perfectly suited for high-precision measuring in all stages of the aluminium making process.

To attain the highest product quality in the process, measuring the roll gap with very high precision is decisive. The RLI 4300 encoder has an accuracy grade that enables 3 μm system accuracy. Thanks to the gateway connection, read-out of diagnostic data from the application is also possible, which enables monitoring of the function of the encoder. The gateway also provides LED indications for warnings and alarms.

Easy to install

Streamline and simplify the rolling process with well-functioning and exact encoders for a perfectly automated measuring system. The Leine Linde RLI 4300 encoders are known for being very easy to install compared to other alternatives on the market. They do not need air compression or filtering, and they are excellent for use in both cold and hot rolling processes. They are well adapted for all metalworking, also aluminium processing, where special consideration needs to be taken regarding the hardiness of the cover, the resistance to certain chemicals and the strength of the gaskets.