Dual output encoders

– complex can be so easy

Did you know that you can use a single encoder for incremental signal speed feedback into the drive system, and simultaneously get an absolute signal for feedback directly into the fieldbus interface of your choice? The dual outputs enable real-time data delivery into your motion control system, in accordance with your needs.

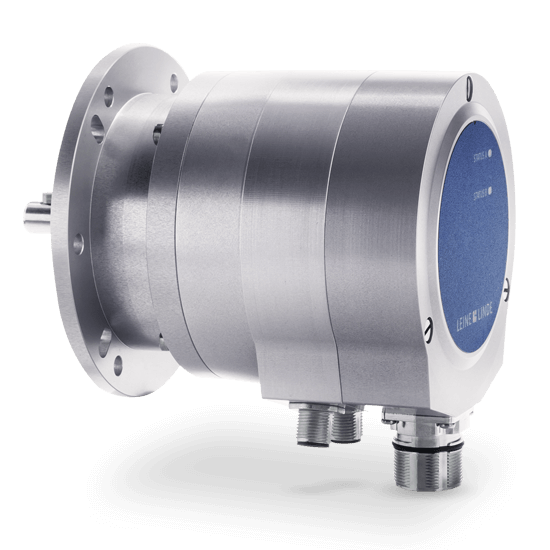

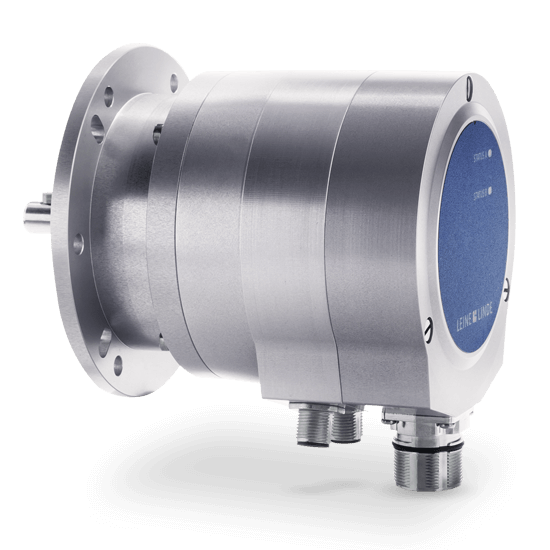

Compact design

The dual output solution saves space on the motor shaft or in the application, as there is need for only one encoder on the spot. Thereby, the mechanical installation takes up significantly less space, as less couplings and adapter components are needed. Furthermore, all encoder models from Leine Linde have a well thought out and compact design, which in itself saves space and makes them easy to install or retrofit. Always reduce maintenance hassle!

Reliable performance

Leine Linde encoders are known for their performance, enduring conditions like high temperatures, moisture, vibration and shock, as well as long working hours. Here are some of the series where dual output signals are available:

- The well-tried 800 series has dual, galvanic isolated outputs for incremental signals as an option.

- Equipped with very large ball-bearings the 900 series is made to serve a long life in operation, and the 1000 series stands up to even more extreme environments with its modular design and a high encapsulation level. These series provide options with dual outputs for both absolute and incremental signals.

- The magnetic 2000 series has got an option with double scanning heads to provide the connected system with redundant signals when needed. Mounted directly on to the shaft without bearings, this encoder is close to indestructible.