6. Hollow shaft or solid shaft encoders?

6.1 Encoders with solid shaft

6.2 Encoders with hollow shaft

6.3 Typical installation errors and the consequences

6.4 Choosing the right shaft type

Should you choose an encoder with a hollow shaft or with a solid shaft? For a retrofit you may want to go for an exact replacement, using the same shaft and flange type as before. That way you will avoid making adaptions on existing machinery. However, in new installations - or where mounting is more difficult - hollow shaft encoders have specific benefits.

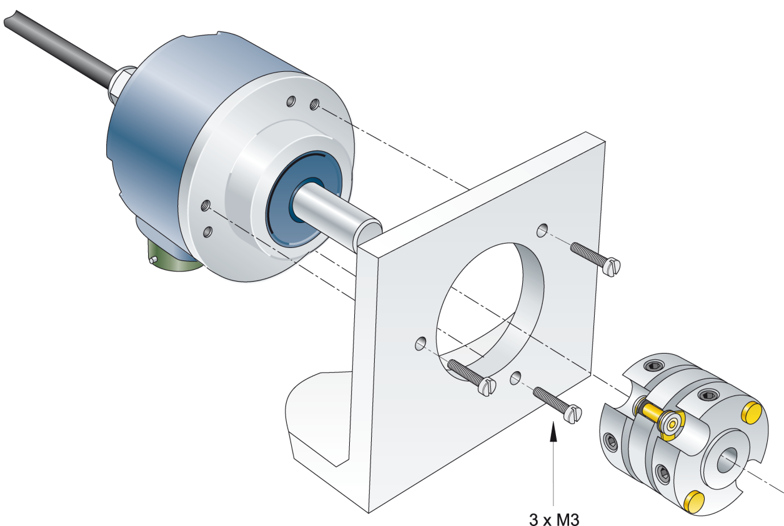

6.1 Encoders with solid shaft

Solid shaft encoders usually require additional mechanical parts for mounting. This adds to the total construction’s length, making it a less good choice in narrow spaces.

A good adjustment of the installation is also essential for the lifetime of the encoder.

Solid shaft encoders:

- Need more mechanics for the installation

- Resultsin longer installations that require more space

- Are sensitive to the installation skill and attention to detail of the person mounting them

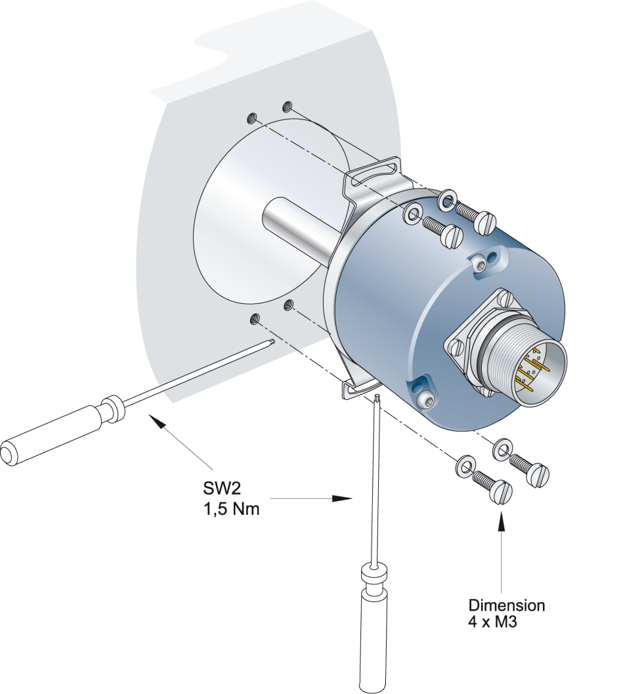

6.2 Encoders with hollow shafts

Hollow shaft encoders are mounted directly onto the machine axis, thus providing a solution which is more compact. As fewer additional components are needed for the installation, this is also a cost effective and low weight solution that minimizes shaft load.

The risk of installation errors is lower with hollow shaft encoders, compared to the corresponding solid shaft encoder models. The risk of alignment errors is minimal in the absolute majority of cases.

Hollow shaft encoders:

- Provide compact installations

- Are easy to mount

- Result in lower shaft loads

- Are cost effective as no extra installation components are needed

6.3 Typical installation errors and the consequences

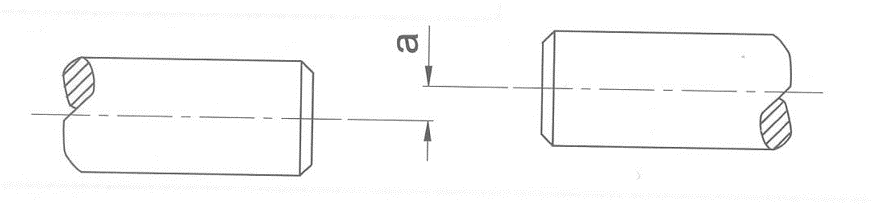

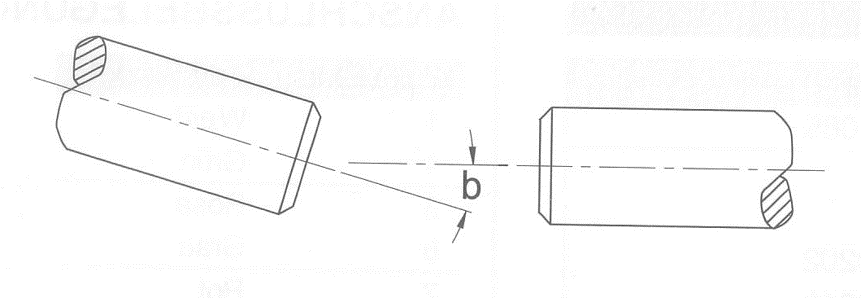

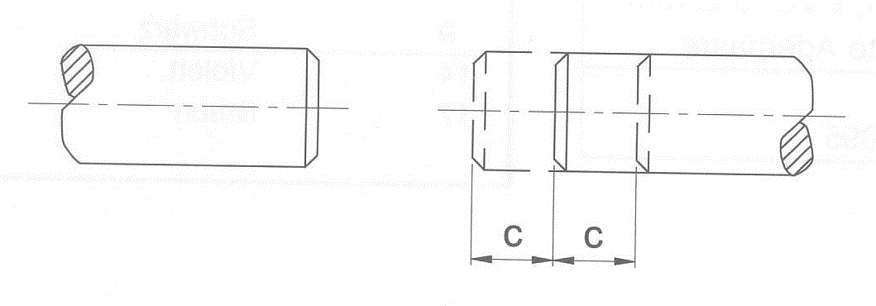

Common installation mistakes include radial misalignment, angle error and axial misalignment.

Radial misalignment

Angle error

Axial misalignment

Installation errors reduce performance and encoder lifetime

Bad installation leads to higher measuring errors from the encoder, increased vibrations to the system as a whole. Increased vibrations will reduce the encoder’s lifetime.

Incorrect encoder installation, generally leads to:

- Reduced lifetime

- Higher measuring errors

- Vibrations in the system that may also affect other components

6.4 Choosing the right shaft type

Unless you have specific reasons to go for a solid shaft encoder, a hollow shaft is often a better choice. Hollow shaft encoders are less likely to suffer installation errors as they are fit directly onto the machine axis and thus, they are less prone to misalignment or angle errors. A properly installed encoder will perform at its best and last longer before it need to be replaced.

Hollow shaft encoders also make for a more compact installation with lower shaft load.