Secure uptime

By providing relevant diagnostics, encoders today are so much more than just encoders. With their condition monitoring functionalities, they enable predictive maintenance and problem-free operation time.

All efforts to reduce operational downtime show clearly on the bottom line. Equipment and machinery parts simply cannot be allowed to fail.

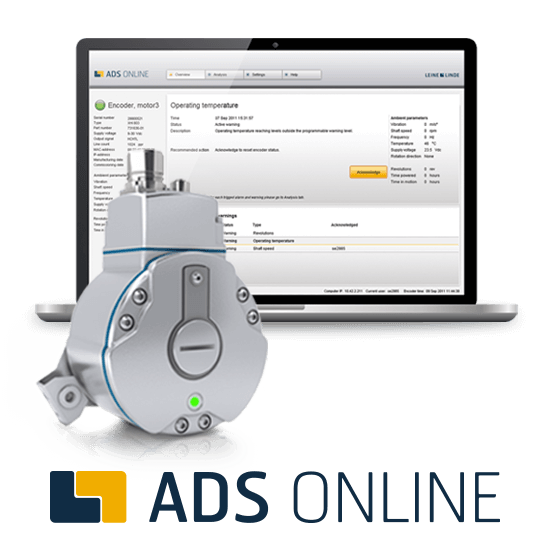

Encoders can be equipped with diagnostic functions to ensure their operating time. They can also provide relevant information about potential sources of failure, which otherwise would risk affecting the production unit as a whole. The placement of the encoder, on the motor or drive shaft, or by some other strategically important moving part, makes it is well suited to collect operational and environmental parameters of importance, like vibrations and temperature variations.

Leine Linde’s built-in condition monitoring solutions make it possible to pinpoint potential sources of failure before problems occur.