ADS Uptime™

– for wireless service check-up or connection via ADS Link

ADS Uptime™ is an extremely useful condition monitoring system for encoders. With local wireless service check-up or system integration with ADS Link, you have maximum flexibility to access data and diagnostics. With ADS Uptime, you can access live data and secure production uptime by making application health monitoring part of your proactive maintenance routine. Knowing things before they happen has never been easier.

Wireless connection with Bluetooth

ADS Uptime is available with wireless connection for Leine Linde’s 800 series. You get remote access to your encoder’s data and diagnostics with Bluetooth in the associated app on your mobile device. In the app, you can customized the alarm levels and then check the data live or look at detailed information for a specific time frame. This give you the tools to manage your maintenance activities.

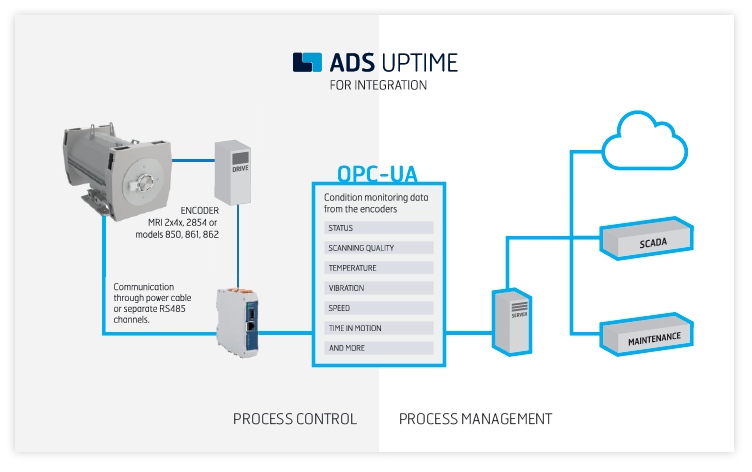

ADS Link – system integration with OPC UA

ADS Link is available for use together with Leine Linde’s 800 and 2000 series encoders. With ADS Link you can integrate the ADS Uptime encoder into your company’s existing maintenance systems.

Warnings and proactive maintenance

Encoders with built-in ADS Uptime will enable monitoring the most relevant data from rotary installations and motors, as well as its surrounding environment. The system has pre-set alarm levels for working environment which are potentially harmful for the encoder, as well as a customer configurable warning system to adapt the diagnostic system to application specific parameters.

ADS Uptime analyses the encoder’s condition and warns for impending faults before they occur. With early warnings of deviation it prevents the risk for potentially occurring problems. Make the encoder check-up part of your proactive maintenance routine to make sure problems are taken care of before they start to exist.

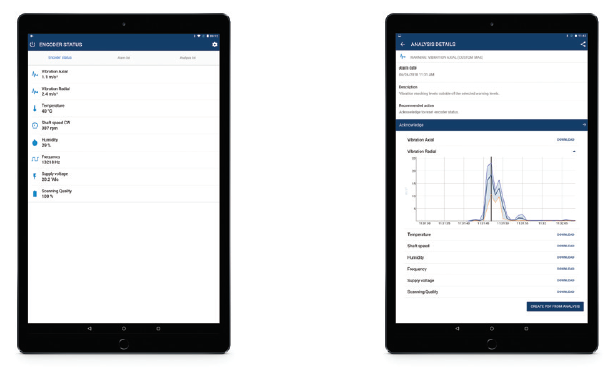

Wireless service check-up and trending

ADS Uptime for wireless service check-up is a tool for simplifying the maintenance routines. Connect thru the app and perform a simple service check-up on the inspection round. Access all the collected data from the encoder. Follow graphs to see the trends of motor performance. In the ADS Uptime app, several factors can be tracked; vibration – axial, radial and tangential, temperature, shaft speed, humidity, and much more. Following these parameters will help detecting trends and influencing factors to start practicing proactive maintenance. Trending is the primary activity to learn failure mechanisms, where understanding, documentation, and sharing of lessons learned will lead the way to a problem-free production.

Warnings and alarm levels can also be set for the different parameters. You will be able to avoid unplanned stops for the motor and drive systems when you have access to all necessary data to make predictions.

History covering the encoder’s entire service life

It is possible to study the graphs with data collected during the encoder’s entire service life. Have the operating conditions changed over time? Increased vibrations can be a sign that the encoder’s motor’s bearings are beginning to wear out. Increased temperature can mean that friction has increased somewhere in the machine and that service is required. The history function continually stores data for all environmental parameters, all the way back to the day when the encoder was first put in service.

Future-proof hardware and easy retrofit

Buy the ADS Uptime for wireless service check-up as part of the encoder models 850, 861 or 862. The ADS Uptime encoder hardware is also prepared for the possibility that the user may later want to integrate data from the encoder into other systems for overall condition monitoring, process management, resource planning, or supervision. The standard encoder cables are used for the encoder installation, and thereby this solution is very suitable for retrofit projects. It works both as a stand-alone solution and with future plans for interconnections to other systems when the need arises.

System integration with ADS Link

With ADS Link, ADS Uptime is integrated into your company’s existing maintenance systems. The ADS Link’s integrated OPC UA server enables two-way communication of real-time data and warnings to any levels in your automation system. You get detailed and reliable information about what is happening at the sensitive shaft end of your motors. You also receive a warning immediately when an impending fault is detected – automatically.