Encoder and sensor solutions for marine & offshore

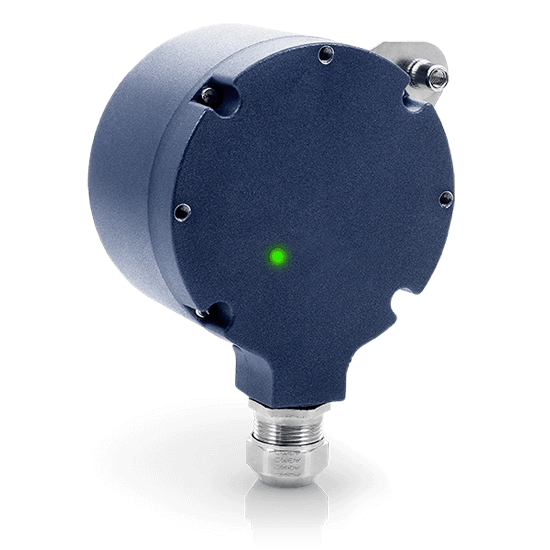

We understand the importance of a reliable and efficient equipment for your operation, which is why we offer marine encoders that deliver outstanding performance, reliability, and durability.

Thanks to their resistance to salt air, salt water, high vibrations, and EMC (Electromagnetic Compatibility), our encoders are suitable for marine and offshore applications. By choosing our DNV Marine type Approved 700 series encoders, you get reliable products that are ready for the toughest challenges.

Contact your nearest Leine Linde office for assistance in picking out the most suitable product for your specific application!

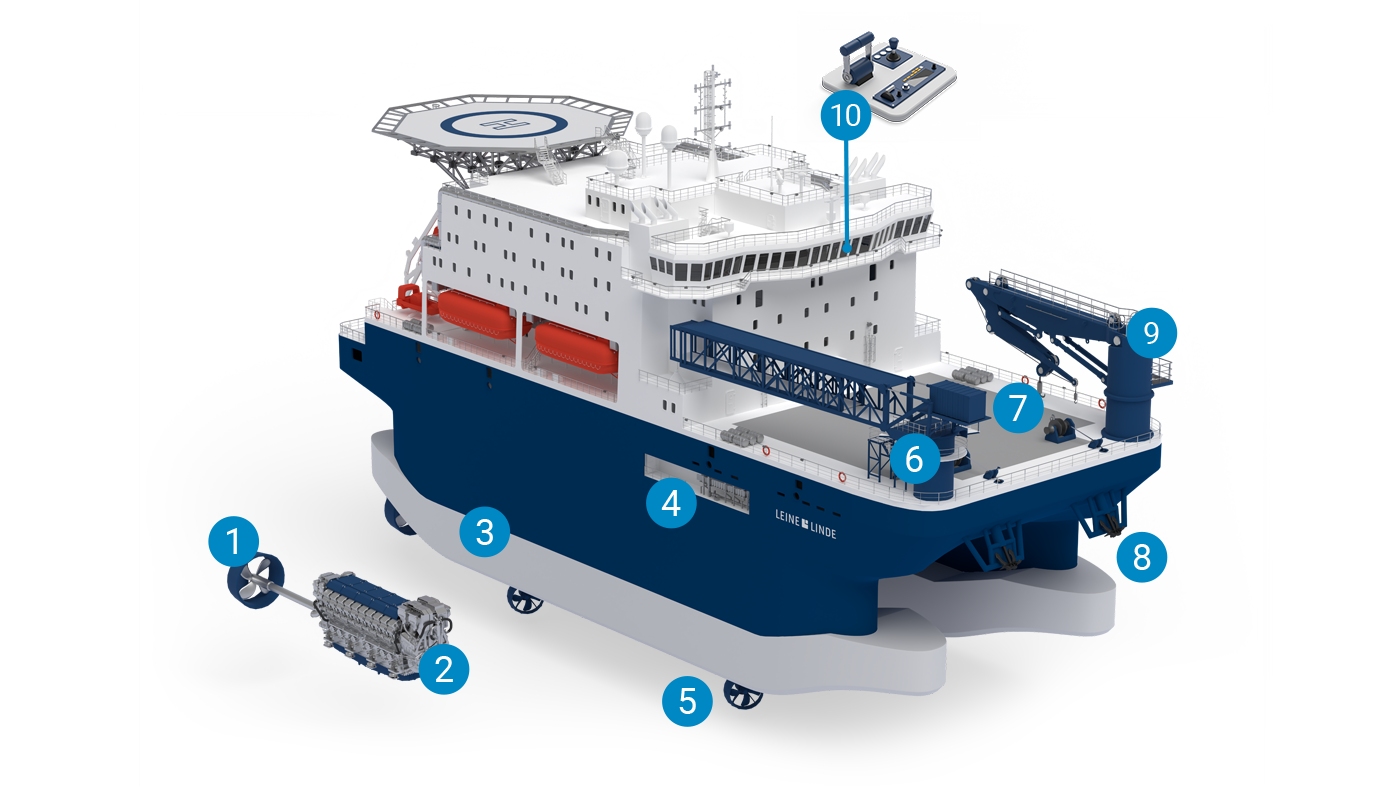

Steering systems

Absolute and incremental encoders can be used in the steering system to monitor the position of the rudder or steering wheel, providing feedback to autopilot systems or assisting manual steering.

Power take-off (PTO)

Encoders can be used to monitor the rotary speed of a PTO system. A power take-off (PTO) on a boat is a mechanical device that allows power from the boat's engine to be transferred to auxiliary equipment or systems onboard. The primary purpose of a PTO on a boat is to provide additional power for operating various deck machinery, auxiliary propulsion systems, or hydraulic systems.

Stabilization systems

Encoders can be integrated into stabilization systems to monitor the movement and position of stabilizer fins or gyroscopic stabilizers, assisting in maintaining stability and reducing vessel roll.

Cargo handling systems

Encoders are integrated into conveyor systems, transfer bridges, and cargo lifts on deck for efficient loading and unloading of cargo, providing feedback on position and speed for automated control and monitoring.

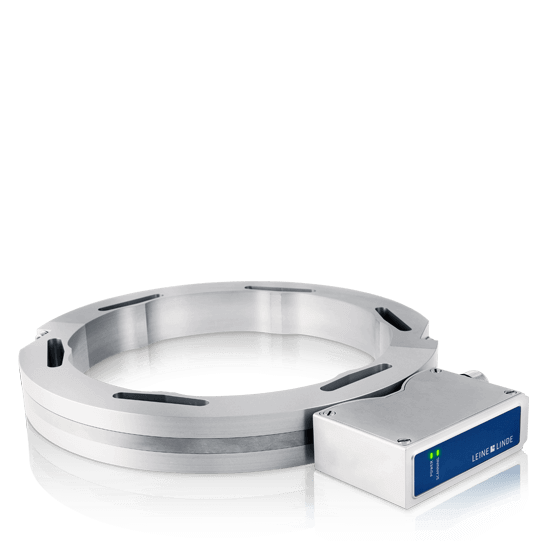

Propulsion & azimuth thruster systems

Encoders can be integrated into propulsion systems to monitor the position and speed of propulsion components such as propellers or thrusters, aiding in precise control and efficiency optimization.

On the main 2-stroke or 4-stroke diesel engine, our 800-series encoders can be used to measure the position of the crank shaft. Purpose of the encoder is usually to optimize the fuel injection and other methods to increase the efficiency of the engine.

Gangways

Winches

Encoders are integrated into winch systems to monitor rope or cable movement during towing, anchoring, or mooring operations, ensuring accurate control and tension management.

Anchor handling systems

Encoders can be installed in anchor systems to monitor anchor deployment and retrieval, providing feedback on anchor position, chain length, and tension for safe and efficient anchoring operations.

Crane & davit systems

Encoders are used to monitor the movement of crane booms, hoists, and trolleys, providing feedback on position and speed for precise cargo handling operations. The encoder can also be used on davit systems for lifting and launching equipment such as tenders or rescue boats, providing feedback on position, speed, and load for safe and precise operations.

Navigation systems

Encoders can be used in navigation systems to monitor the rotation and movement of radar antennas, satellite dishes, or other directional antennas, aiding in accurate alignment and tracking.