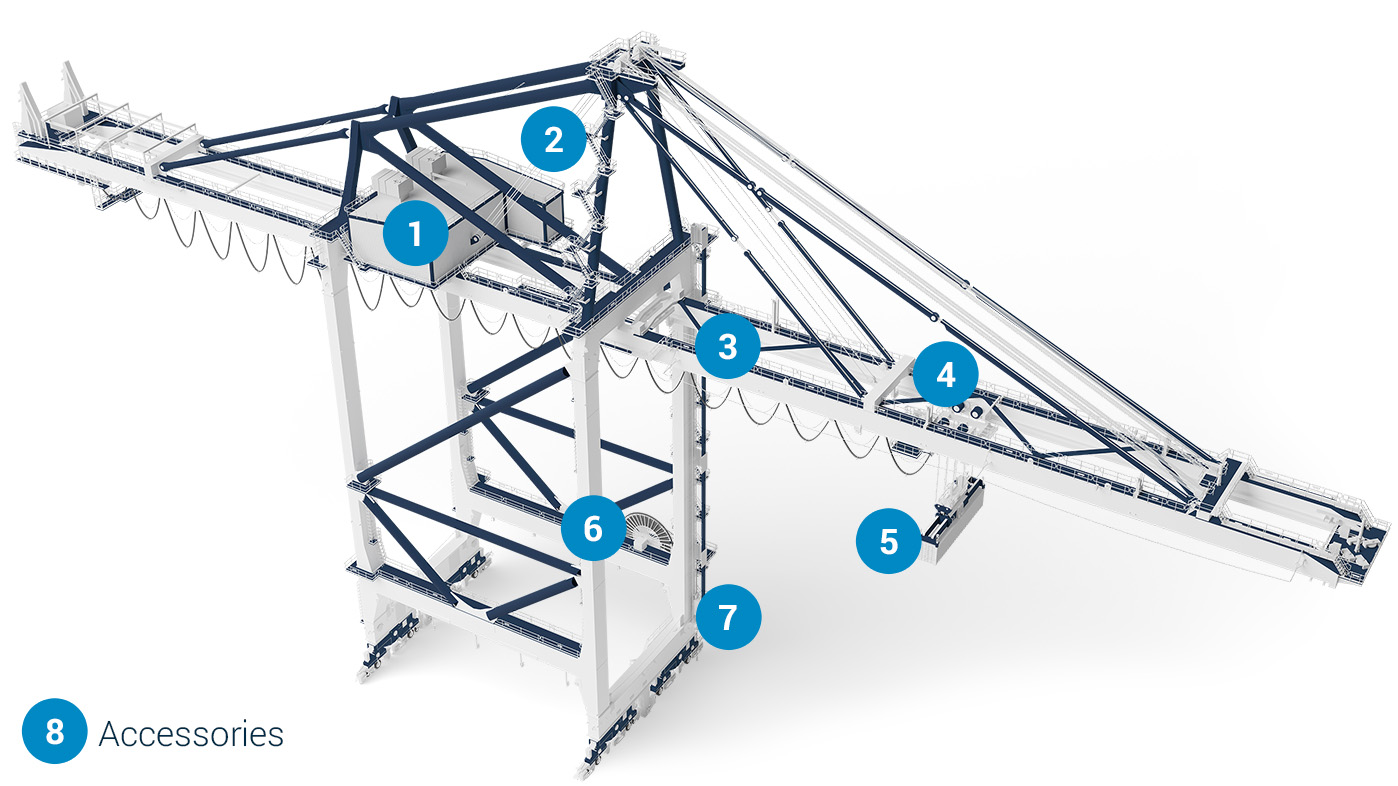

Encoders for the crane industry

Cranes operate in environments where safety, precision, and uptime are critical. Whether in ports, steel plants, or construction sites, Leine Linde encoders are built to deliver reliable feedback for motion control—even under heavy loads, vibrations, and extreme weather conditions.

Trolley position

Trolley control depends on quick, precise and reliable encoder feedback for predicable results based on operator input. Incremental Leine Linde encoders are used for speed feedback to drives controlling the trolley motors, while absolute encoders on the trolley drum are used to measure position.

Boom position

The boom hoist control gets its feedback from encoders on the motor and on the drum. Robust encoders, suitable for the demanding environment is crucial for reliable operation and minimal downtime. This is an environment where Leine Linde encoders have a spotless reputation. Add encoders with integrated safety functionality (FSI) as needed for your application.

Load monitoring

Strain sensors provide data that can be used for bending moment calculations as well as fatigue load monitoring. This data is vital for the main structural parts such as the boom of the crane. Thanks to the pure digital data transmission, an easy connection to the crane automation system is already prepared.

Hoist control

For the crane main hoist, Leine Linde’s incremental encoders are used for speed and position monitoring and to detect overspeed, underspeed or standstill. Absolute encoders mounted on the drum provides position data and to provide speed related alarms, sometimes through a separate speed monitor. Encoders with integrated functional safety (FSI) can be connected directly to a safety loop or emergency brake.

Spreader position

Spreader control requires fast and precise encoder feedback that will produce repeatable and reliable results for the operator. Leine Linde incremental encoders is the perfect, robust solution for the speed control while our absolute encoders, are used for position measurement.

Cable reel rotation

Make sure the power cable is not stretched and damaged by using an encoder to keep track of the cable reel’s position.

Travel control

For efficient, just-in-time operations in the harbor, STS, RTG and RMG cranes need to move to a new position several times per day. For these crane types, Leine Linde encoders provide accurate gantry position feedback through a wide variety of fieldbus and communication protocols.

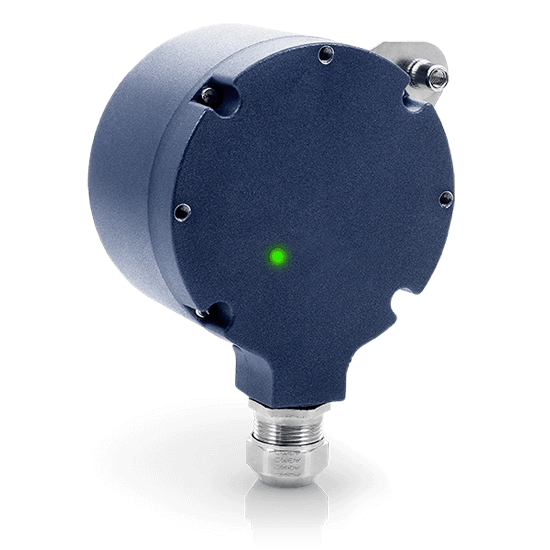

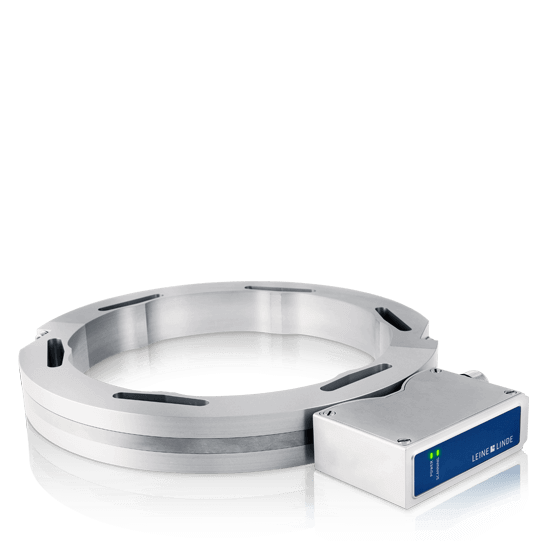

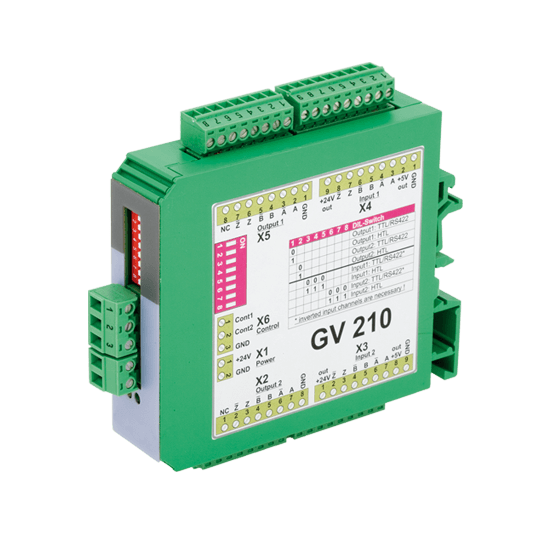

Accessories

Leine Linde offers a wide range of accessories for our encoders. This is a selection relevant for crane applications. Please contact your nearest Leine Linde sales office if you have a specific request.

Reliable performance in lifting systems

Our encoders are used in hoists, trolleys, slewing mechanisms, and gantry systems to ensure accurate speed and position control. With robust mechanical design and high ingress protection, they support safe and efficient crane operations in both indoor and outdoor settings.

Key applications

-

Hoists and winches – for load positioning and speed regulation

-

Trolley and bridge travel – for synchronized movement and collision avoidance

-

Slewing and luffing systems – for precise angular positioning

-

Port and container cranes – for high-speed, high-precision operations

-

Tower and mobile cranes – for reliable feedback in dynamic environments

Tailored solutions for crane systems

-

We provide encoder solutions designed to meet the specific demands of crane applications

-

Incremental and absolute encoders for various control architectures

-

Heavy-duty designs with shock and vibration resistance

-

Custom mechanical and electrical interfaces

-

Condition monitoring options for predictive maintenance

Why Leine Linde

-

Proven performance in demanding lifting environments

-

Long service life with minimal maintenance

-

Global support and fast delivery

-

Expertise in customization for crane and hoist systems