Mining innovation in motion: Vale’s Magic Cube powered by 800 ADS Online

Smart engineering meets savings—Vale’s new solution reduces costs and drives progress

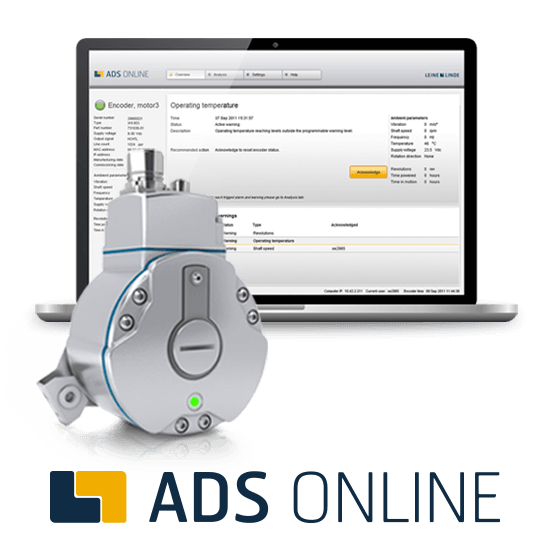

Vale, one of the world’s leading mining companies, has implemented a transformative maintenance solution in partnership with HEIDENHAIN Brasil and Leine Linde. With Leine Linde’s 800 ADS Online encoder series, Vale has significantly reduced operational costs and improved maintenance efficiency.

Partnership for innovation

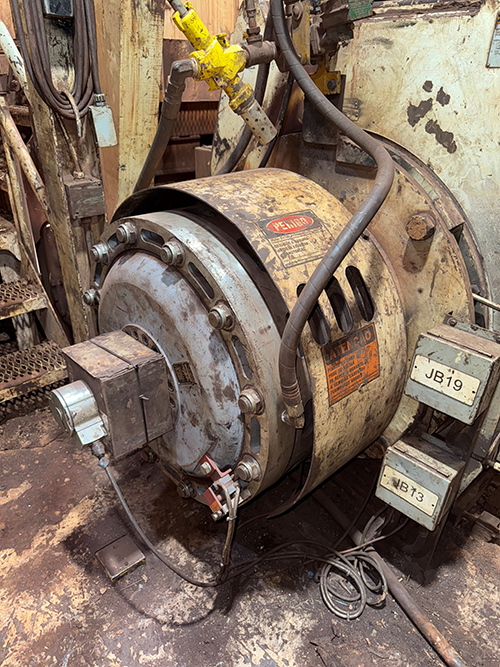

In collaboration with HEIDENHAIN Brasil and Leine Linde, Vale developed a tailored solution: the “Magic Cube.” This custom support system integrates Leine Linde’s 800 ADS Online encoder series, known for its durability and real-time diagnostic capabilities, to streamline maintenance procedures and reduce operational disruptions.

Reduced downtime, increased productivity

The innovation, known as the “Magic Cube,” was designed to address the high costs, extended downtime, and safety risks associated with traditional encoder replacement processes. Through close collaboration and technical innovation, the solution has delivered measurable business value:

-

93.3% reduction in encoder replacement time

-

60% less manpower required for maintenance

-

87% annual savings per unit replaced

-

Significantly improved safety for maintenance personnel

Scalable solution

This strategic upgrade has not only optimized maintenance operations at Vale’s Carajás site but is also being scaled across other key locations in Brazil. The success of the project underscores the value of combining robust industrial technology with a forward-thinking approach to asset management.

With Leine Linde’s robust 800 ADS Online encoders at its core, Vale’s new maintenance standard is setting the pace for innovation in large-scale mining.