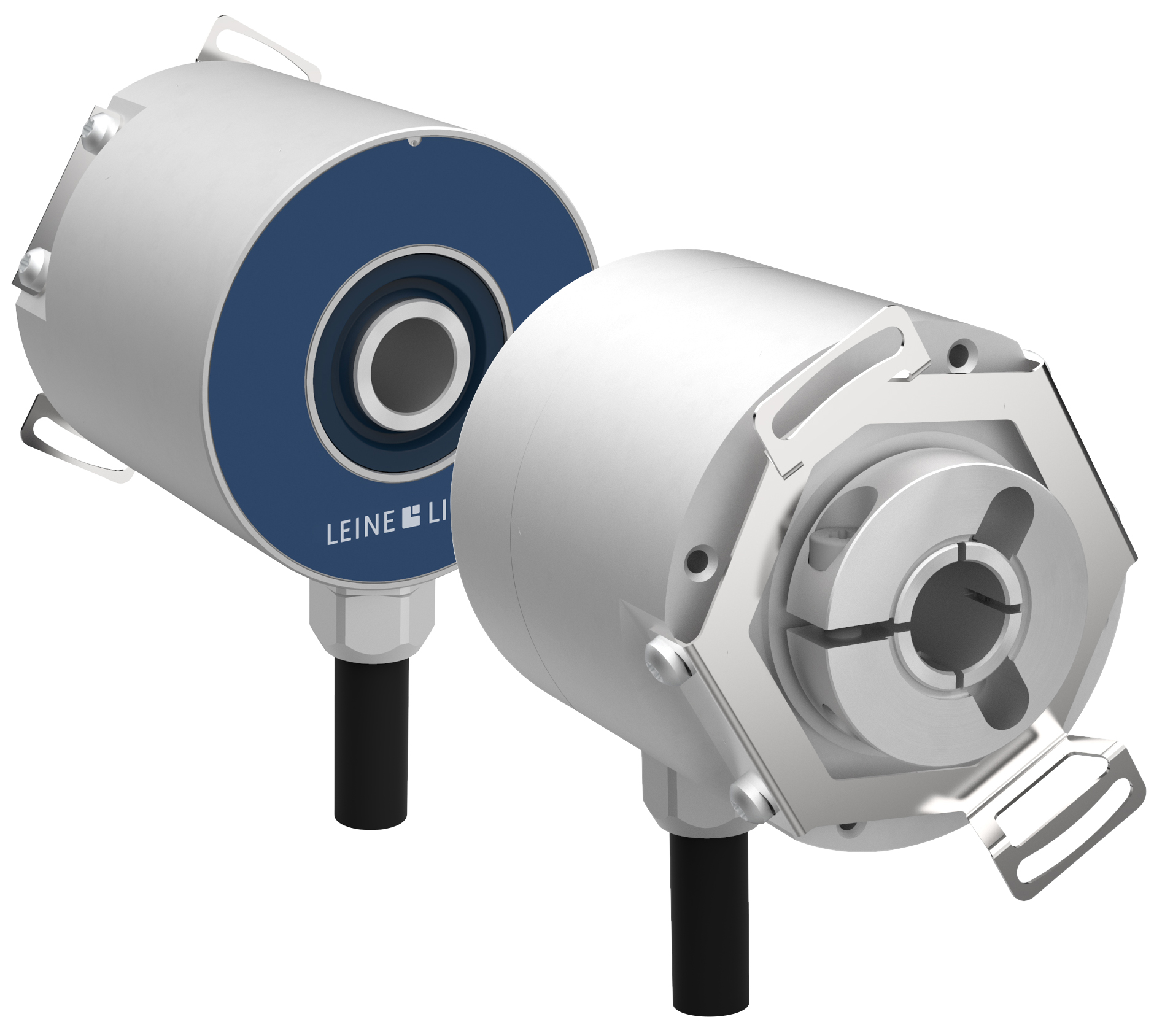

MZI 594 - bearingless

Developed in collaboration with wind turbine manufacturers

This inductive incremental encoder was developed to deliver: long lifetime, minimized impact on performance due to environmental conditions and ease of installation and commissioning. The result is an inductive ø58 mm incremental encoder in a bearingless design.

With the use of inductive scanning, the encoder can deliver high resolution, up to 8192 pulses per revolution, with high accuracy. Its lifetime is not restricted by wear on the bearings. The bearingless design also make for a very compact solution. The unique sliding shaft design automatically compensates for movements of the generator or motor rotor shaft caused by thermal expansion.

-

Superior lifetime due to bearingless design

-

Sliding shaft arrangement to compensate for thermal impact

-

Scanning quality is unaffected by humidity, dust and other contamination

-

Resistant to electrical or magnetic fields due to the inductive scanning technology

-

Compact (ø58 mm x 45 mm) and very easy to install correctly

-

Class IP69K

Get in touch!

At Leine Linde, we take great pride in giving you personal support. Please contact us for assistance and technical support. All questions are welcome! We work worldwide.