Structural load monitoring

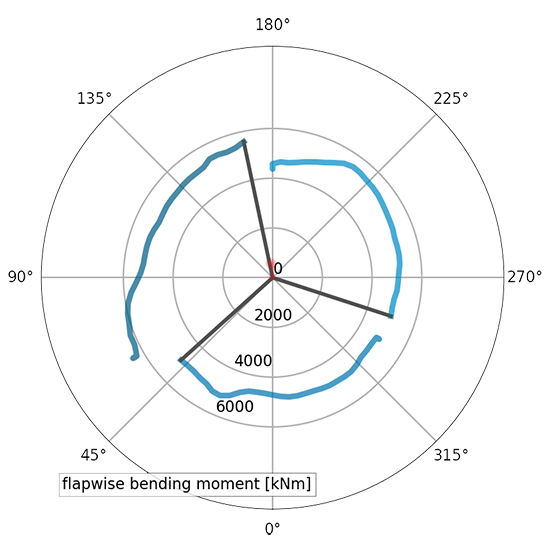

Online structural load monitoring offers a number of advantages. By using strain sensors on a static or moving structure, stress and signs of fatigue can be recognized at an early stage, and measures can be taken to avoid damage. In a sensor-actuator system, sensor-based monitoring together with its precise measurements and system calculations can be used as input variables for a control system. The system can then dynamically adjust the movement of the structure in order to reduce harmful loads.

Structural load monitoring can:

- reduce both the installation and material costs,

- facilitate maintenance and reduce the need for maintenance,

- increase the lifetime of your machine, structure, or the facility as a whole.

If, for example, the rotor blades in a wind turbine are optimized for harvesting maximum energy, harmful loads can still be kept at a very low level, by help from a sensor-actuator system based on strain sensors in the rotor blades. In a highly dynamic system, mechanical stress in the tower and foundation can be reduced. Thanks to continuous recording of the structural loads, a life cycle report can be made for the whole time of operations.

This means that by using a monitoring system, the whole facility can be designed with smaller components and without excess materials, since the loads on the construction will decrease significantly. The cost is reduced, not only for the basic investment, but for transport, erection, and maintenance. In addition, the lifetime will be extended thanks to monitoring, registration and control of harmful loads.

Leine Linde provides solutions with different levels of system integration for structural load monitoring. From robust sensors and components up to system applications tailored for specific needs!